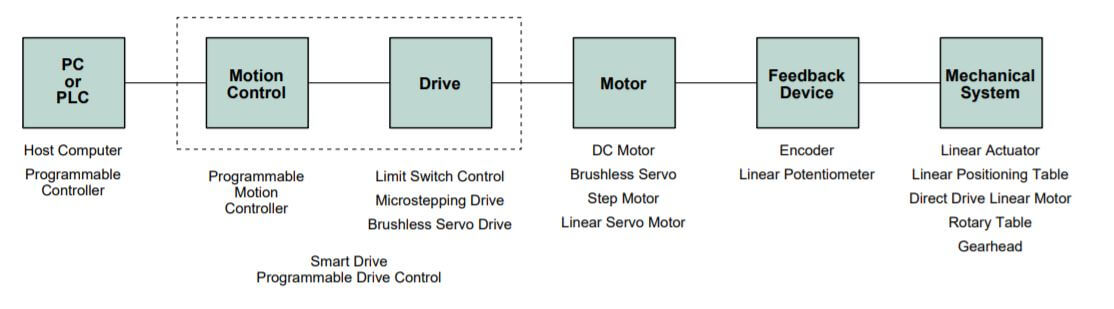

Many different components are used in a variety of combinations to create a complete motion control or positioning system. IDC offers the broadest range of products spanning the complete spectrum from mechanical actuators to microstepping and brushless servo drives to programmable motion controllers. A successful application depends on choosing the right combination of actuator, motor, drive, and control technology. More than one technology may meet the requirements of your application. In this case, factors such as performance, cost, flexibility, and simplicity may determine your selection.

Introduction to Motor Technologies

DC Motor Systems

DC motors are used with IDC’s DC motor controls to control velocity and position. With these simplecontrols, limit switches attached to the actuator or thecustomer’s load provide position feedback. DC motors are also used with analog position controls and a linear potentiometer for position feedback. The result is an absolute positioning system. They can also be used in closed loop servo systems with an incremental encoder for position feedback. DC motors have windings on the rotor of the motor. To supply current to the rotor, a set of brushes ride on a segmented commutator, which supplies current to the appropriate internal windings depending on the position of the rotor. Brushes may need to be replaced periodically, depending on the load, speed and duty cycle. The commutation method limits the top speed that can be reached before arcing over the commutator segments occurs. The heat generated in the windings must travel across the air gap and the through stator to be dissipated. This long thermal path results in a motor that is less thermally efficient and is therefore larger than a brushless motor with an equivalent power rating. The windings also add inertia to the rotor, which results in lower peak acceleration rates than a similar brushless motor.

Advantages

Common Applications

Advantages

Disadvantages

Common Applications

Advantages

Disadvantages

Incremental encoder with commutation channels. The process of steering current through the appropriate motor windings in order to produce output torque is called commutation. In brush motors, commutation is performed electro-mechanically via brushes and the commutator. In brushless motors, commutation is performed by electronically steering the current to the appropriate winding. To do this, the rotor position must be determined. A circuit board containing the Hall devices is aligned with a magnet on the rotor, so that the relationship shown between the Hall outputs and the motor back EMF can be established. When a brushless motor is used in a servo application requiring position feedback, room must be made for both the commutation circuit board as well as the encoder. This generally adds both cost and complexity to the motor package. Encoders are now available with integrated commutation outputs equivalent to those produced by Hall devices. The result is a more compact system, reduced alignment time and superior switching accuracy, due to the much lower hysteresis of the encoder when compared to a Hall device. Adding additional data tracks to the encoder disk provides the commutation outputs.

Be the first to learn about classes, training, webinars, products news and more.

We use only necessary cookies on this website to provide the best user experience and customer service.