MOTORS & VFDs

Industrial Robots for Manufacturing

Omron’s robotics lineup includes Collaborative Robots, SCARA, Mobile and Parallel robotics – all designed to help manufacturers meet today’s production demands and automation challenges.

Omron’s robotics lineup includes Collaborative Robots, SCARA, Mobile and Parallel robotics – all designed to help manufacturers meet today’s production demands and automation challenges.

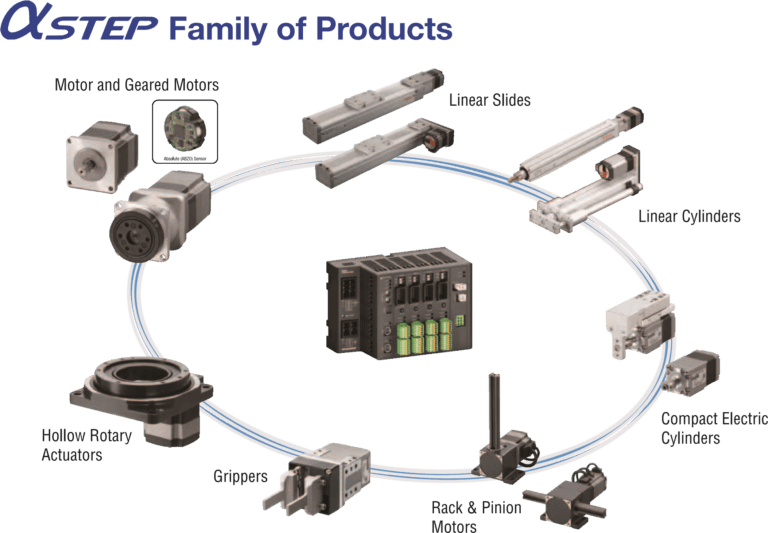

The AlphaStep AZ Series stepper motors offer high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires AlphaStep AZ Series Stepper Motor Driver.

Resources

Download the whitepaper.

Download the ebook.

Download the ebook.

Give us a call and get help right away. We're here for you!

Got a question or need more info? Contact us!

Get pricing quickly. Fill out our Request For Quote form.

©2025 MSI TEC, Inc ALL RIGHTS RESERVED

©2025 MSI TEC, Inc ALL RIGHTS RESERVED

We use only necessary cookies on this website to provide the best user experience and customer service.