Barcode Readers and Traceability Solutions for Automation and OEM Applications

Featured Traceability Products

MicroHAWK V430 Fixed-Mount Ethernet Barcode Readers

The MicroHAWK V430-F is the next generation of barcode readers with expanded functionality. It's the smallest IP65/67-rated on the market and features Liquid Lens Auto-focus and multiple lighting options.

LVS-9585 Handheld Barcode Verifier

Offers advanced lighting options and powerful software functionality. Enables users to automatically find the DPM symbol within the verifier field of view, and cycle through the lighting settings to find the lighting type that works best with the specific DPM marking and materials.

Omron MX-Z Fiber Laser

Marker

Fiber laser markers provide a flexible and reliable method for permanently marking parts across many industries. high quality, permanent identification with scaling capabilities to add functionality to the process like product traceability or position compensation.

Traceability solutions for your industry

Food & Beverage Packaging

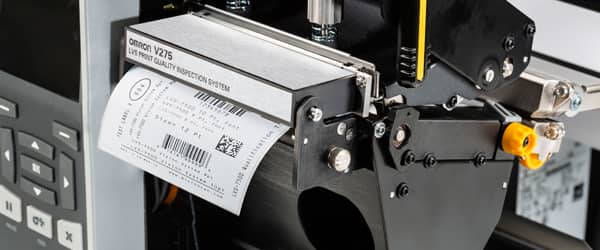

Avoid recalls and liability with traceability and print quality inspection.

In the food and beverage industry, labels must list ingredients that match the products contained in the packaging. Labeling errors result in recalls when undeclared allergens are found to endanger the health of consumers. If you’re not taking active steps to avoid these labeling errors, it’s time to start doing so. One of the best ways to combat this issue is to implement an industry-standard label verication system.Learn about the latest trends, challenges and strategies in food and beverage packaging traceability.

Medical & Life Sciences

The FDA’s Unique Device Identification System final rule (UDI Rule) requires medical device manufacturers to include a unique device identifier on all device labels and packages. Neglecting to do so can result in FDA warning letters or recalls. To ensure accuracy on device labeling, barcode and label quality verification is essential. In-line inspection systems feature OCR, OCV and blemish detection that together provide 100% label inspection against a label reference image and expected label content. Learn strategies for ensuring regulatory compliance and transitioning to an automated lab.

Semiconductor & Electronics

Utilize data and streamline your process to survive. In today’s intense competition, companies must utilize data and automation to streamline their processes and ensure a consistently high level of quality. Data-driven traceability systems composed of barcode readers, vision technology, marking equipment and verification solutions can help companies squeeze much-needed profits from a highly competitive industry. Discover trends, challenges and solutions and how a traceability system can increase profitability.

Automotive

As part of a holistic traceability solution, many automotive parts need to bear direct part marks (DPMs) to remain identifiable throughout the life of the vehicle. Wear and tear degrades the mark’s readability over time. A comprehensive grading system is necessary to evaluate the quality at time of marking. Automotive manufacturers can use the MicroHAWK F430 industrial Ethernet smart camera optional liquid lens autofocus to check DPM quality. Paired with an Omron ISO/IEC compliant barcode verifier the F430 helps you keep codes in line with ISO/IEC 29158 standards. Learn how to maximize the benefits of a real-time traceability system and minimize the number and impact of recalls.

Resources

Case Study: Automated Bottling Line for CBD Industry

This case study discusses the design of a compact CBD concentrates bottling line that addresses the needs of smaller, more space-constrained players in the industry.

Improve Labeling Speed and Accuracy

Discusses a medical device manufacturer need for improved labeling speed and accuracy as demand increased across its several facilities.

Staying Up To Date On Traceability In The Medical Industry

Strategic solutions for complying with medical device regulations and automating the clinical laboratory and

medical industry.

Contact us to learn how label inspection and verification technologies can help you.

Call 866.397.7388

Give us a call and get help right away. We're here for you!

Get in touch

Got a question or need more info? Contact us!

Request a Quote

Get pricing quickly. Fill out our Request For Quote form.