What is a Parallel Robot?

Parallel robots have multiple axes (at the tip) that move in parallel and have stationary drives and gears. They offer high precision and speed, and are generally used in pick & place applications. Parallel robots integrate the robot controller and servo drive, saving valuable floor space. Omron’s Hornet and Quattro parallel robots are used in industries like packaging, food and beverage, healthcare and pharmaceutical. Omron Quattro series has four axes and a high payload capacity. The Hornet 365 series has 3 to 4 axes and payloads between 3kg – 8kg. Yaskawa’s Motoman MPP is a 4 axis parallel robot with a payload of 3kg.

Omron iX3 Parallel Roboti

Parallel robot ideal for use in the food and beverage, pharmaceutical, and healthcare industries

The iX3 is a parallel robot for high-speed picking and packaging applications, perfect for primary and secondary food packaging. The powerful controls are fully embedded into the base of the robot, saving valuable floor space and reducing installation costs and complexity. It features a hygienic design that minimizes contamination risks, including a standard IP65-rated work area and corrosion-resistant materials for easy washdown.- EtherCAT connectivity to the Omron NJ501-R controller and programming through the familiar IEC 61131-3 programming language or scripting (eV+).

- Tracks up to a conveyor speed of 1.4 m/s

- Designed with a high payload to support multi-hand (multi-picking)

- Supports fast Pick & Place on a fast conveyor

- Helps reduce mounting cost and robot vibration

- Maximum working diameter: 1,130 mm

- Working height: 425 mm

- Maximum payload: 8 kg

- Weight: 52 kg

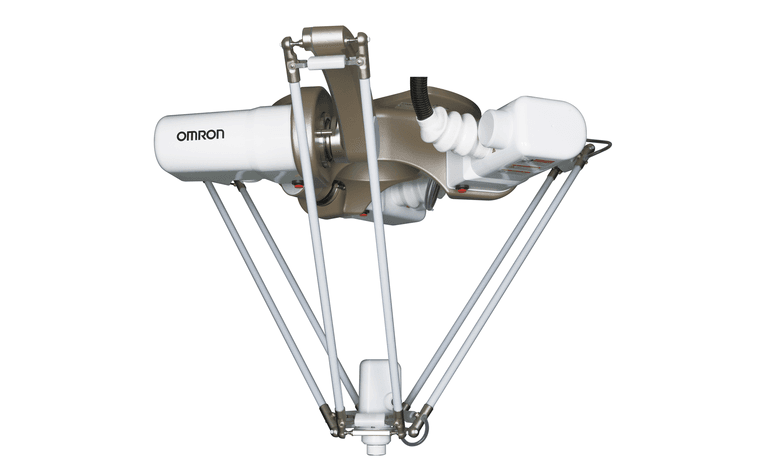

Omron iX4 Parallel Robot

Four-axis parallel robot achieves high speed and high precision

The iX4 Parallel robot excels at high-speed applications in packaging, manufacturing, assembly and material handling. It is the only parallel robot (or “delta robot”) in the world with our patented four-arm rotational platform, delivering maximum speed, maximum acceleration and exceptional performance across the entire work envelope. Ultra-compact controls and embedded amplifiers improve footprint efficiency while simplifying installation.- EtherCAT connectivity to the Omron NJ501-R controller and programming through the familiar IEC 61131-3 programming language or scripting (eV+).

- Four-axis arm evenly distributes the load on the robot

- Fast and high-precision conveyance and assembly

- Designed with a high payload to support multi-hand (multi-picking)

- Supports fast Pick & Place on a fast conveyor

- Meets the sanitary standards of the United States Department of Agriculture for prevention of product contamination

- Maximum working diameter 1,300 mm

- Working height 500 mm

- Maximum payload 15 kg

- Weight 117 kg

Omron Hornet 565 Parallel Robot

Omron Adept Quattro Parallel Robot

The Omron Adept Quattro robot is the only parallel (or delta robot) in the world that is offers Omron’s patented four-arm rotational platform and is USDA/FDA approved for meat and poultry processing. The Quattro Parallel robots are designed for high-speed applications like packaging, manufacturing, assembly, and material handling. They deliver maximum speed and acceleration with exceptional performance across the entire work envelope. The compact controls and embedded amplifiers provide an extremely efficient footprint and simplifies installation.

Omron Sysmac Delta Robot

Omron offers 3 types of Delta robots: Delta, Mini Delta and Washdown robots. Omron’s Sysmac Delta Robot is the fastest picking system in the Sysmac platform achieving up to 200 cycles per minute. It can be synchronized with multiple conveyors to perform impromptu Pick & Place operations. Robot control is integrated in Omron’s NJ controller which can control up to 8 Delta robots with one controller. or 1 ms when controlling up to 4 robots. These Omron Delta robots are low maintenance and have components that are easy to access.

Yaskawa Motoman MPP Series

Yaskawa Motoman’s MPP3S series is a high speed delta robot that is designed for high-speed picking operations like pick and place, kitting, assembly, packaging and cartoning. It’s CPM rate includes 0.04 second per cycle for part acquisition and release. The Motoman MPP3H series is ideal for packaging applications like pick & pack, pick & place, assembly and part transfer, with performance optimized for payload. Both models have a compact, zero-footprint design for high-density work spaces and can be adapted for many application layouts. Because the MPP series has NSF-H1 certified food-grade lubricants and anti-corrosive coating, it offers greater application flexibility and can handle a wide variety of products.

Videos

Omron Demo: Adept Quattro Parallel/Delta Robot

Omron Hornet 565 Parallel Robot Picking & Packaging Applications

Let us help find what you need.

Call 866.397.7388

Give us a call and get help right away. We're here for you!

Get in touch

Got a question or need more info? Contact us!

Request a Quote

Get pricing quickly. Fill out our Request For Quote form.