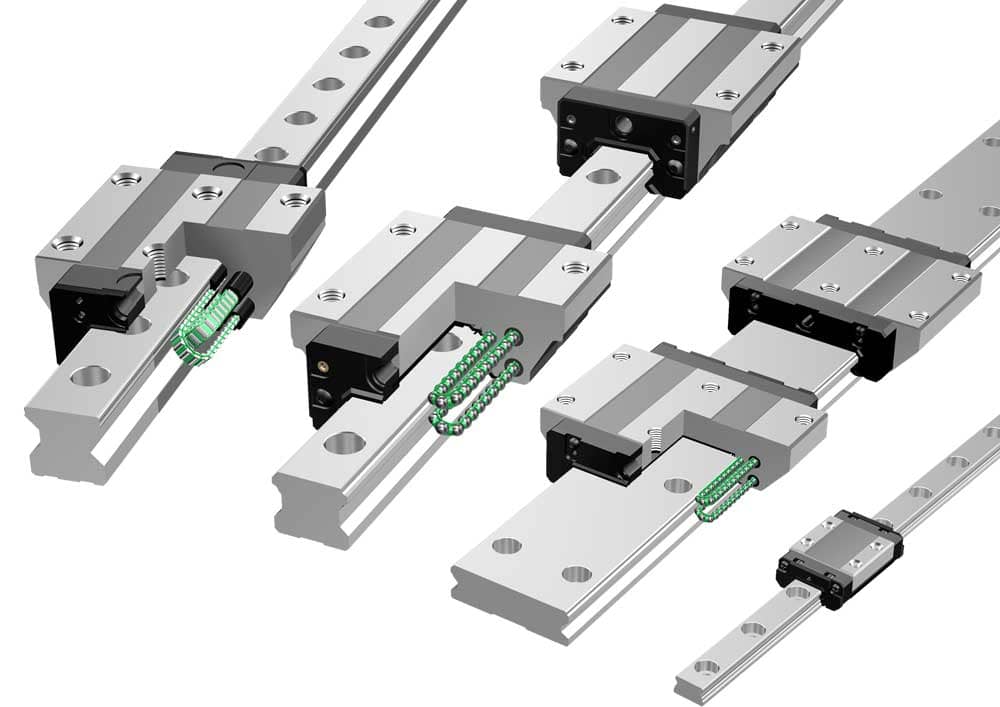

THK Linear Motion

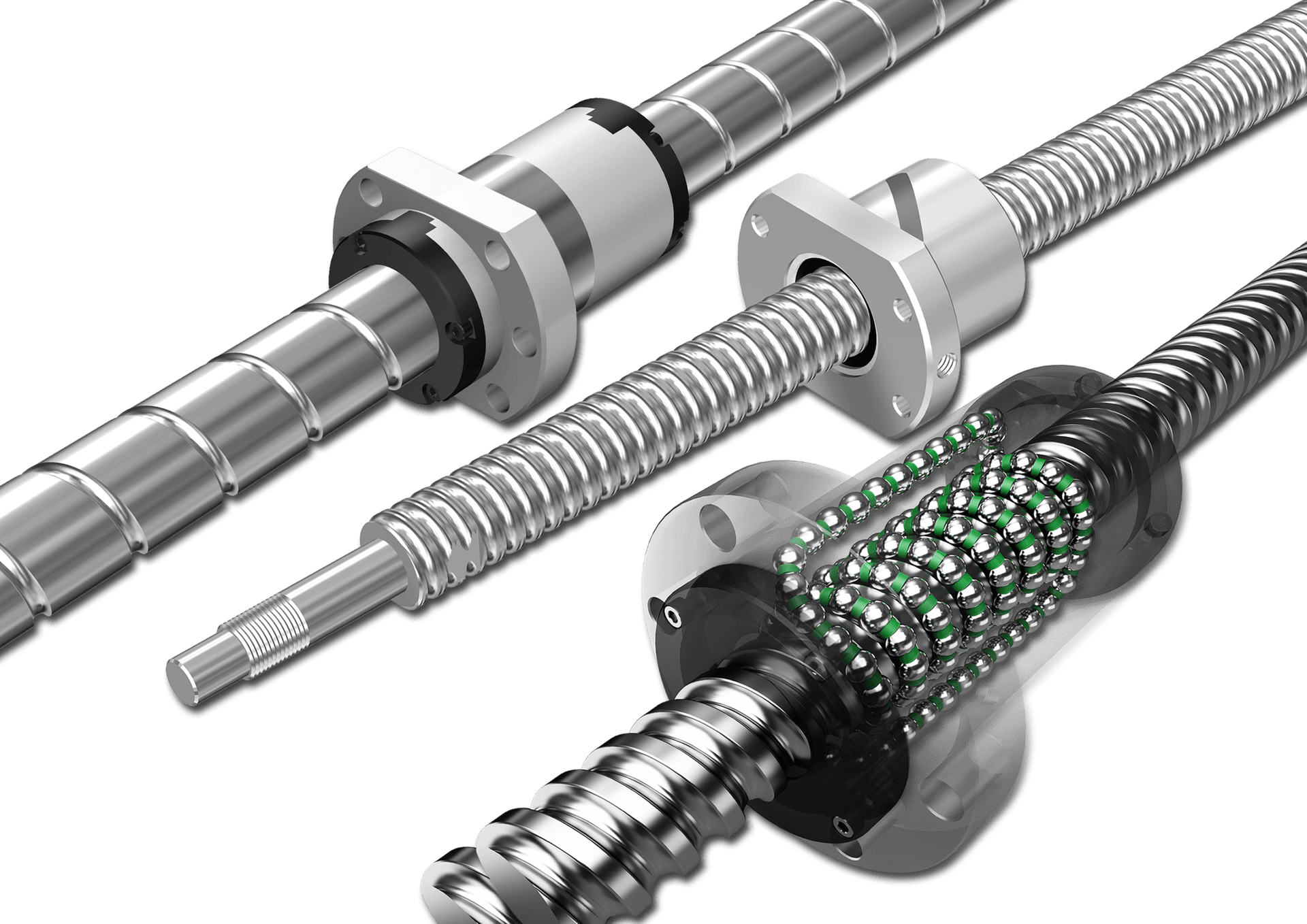

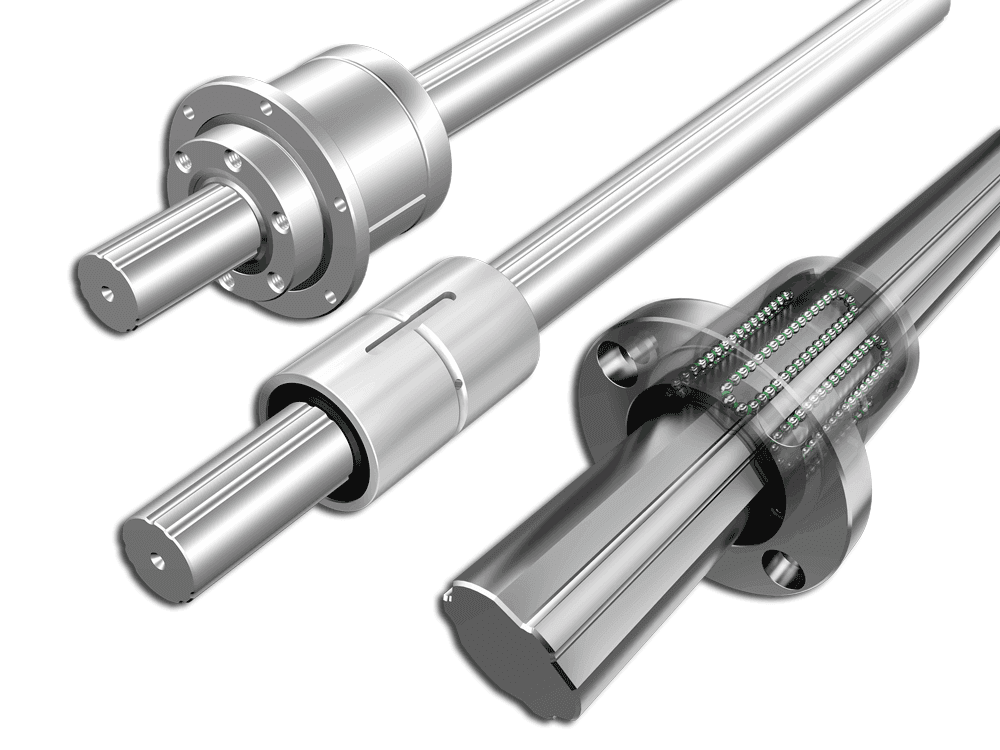

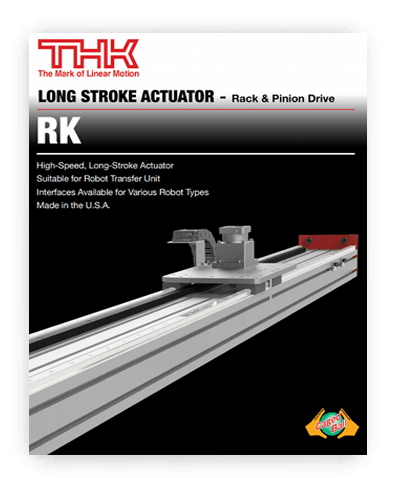

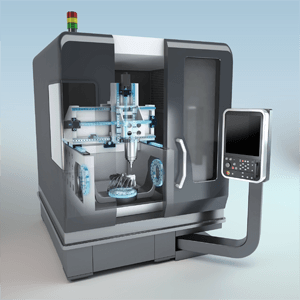

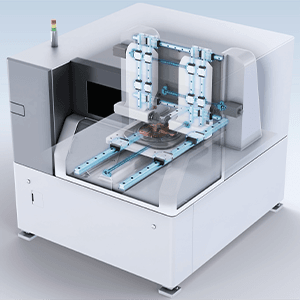

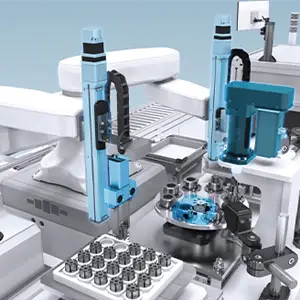

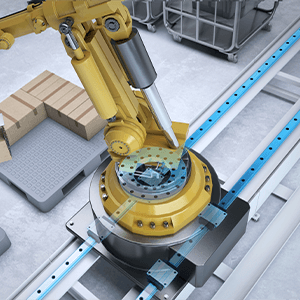

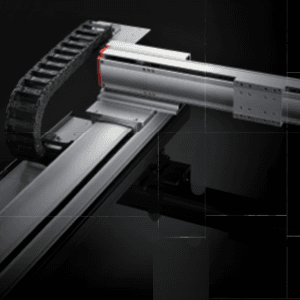

THK pioneered the first linear motion (LM) Guide system in 1972, which realized the mechanism of rolling contact to linear motion and are now an indispensable component of mechanical and electronic systems in the world. The linear motion system plays wide-ranging roles not only in NC machining tools and industrial robots, but also in the electronics industry including semiconductor and liquid crystal manufacturing facilities. THK has also developed many other unique mechanical components, including the LM Guide with Caged Ball Technology, Ball Spline, Ball Screws and Link Balls.