Automate anything with Collaborative Robots

Collaborative robot technology is now accessible to companies of all sizes. Robotic arms can be implemented in virtually any industry, in any process, and by any employee. And cobots deliver the flexibility and financial return that manufacturers need to compete and win in any market condition. The flexibility and ease of implementation of collaborative robots allow manufacturers to overcome staffing issues, improve product quality, and to produce goods during off-hours, frequently running some tasks “lights out” overnight.Solve your labor needs, increase productivity & improve quality with Collaborative Robots

Cobots give manufacturers access to all the benefits of advanced robotic automation, without the extra costs associated with traditional robots: difficult programming, long set-up, and shielded work cells. This makes automation affordable even for small-batch production runs and mixed product assembly.

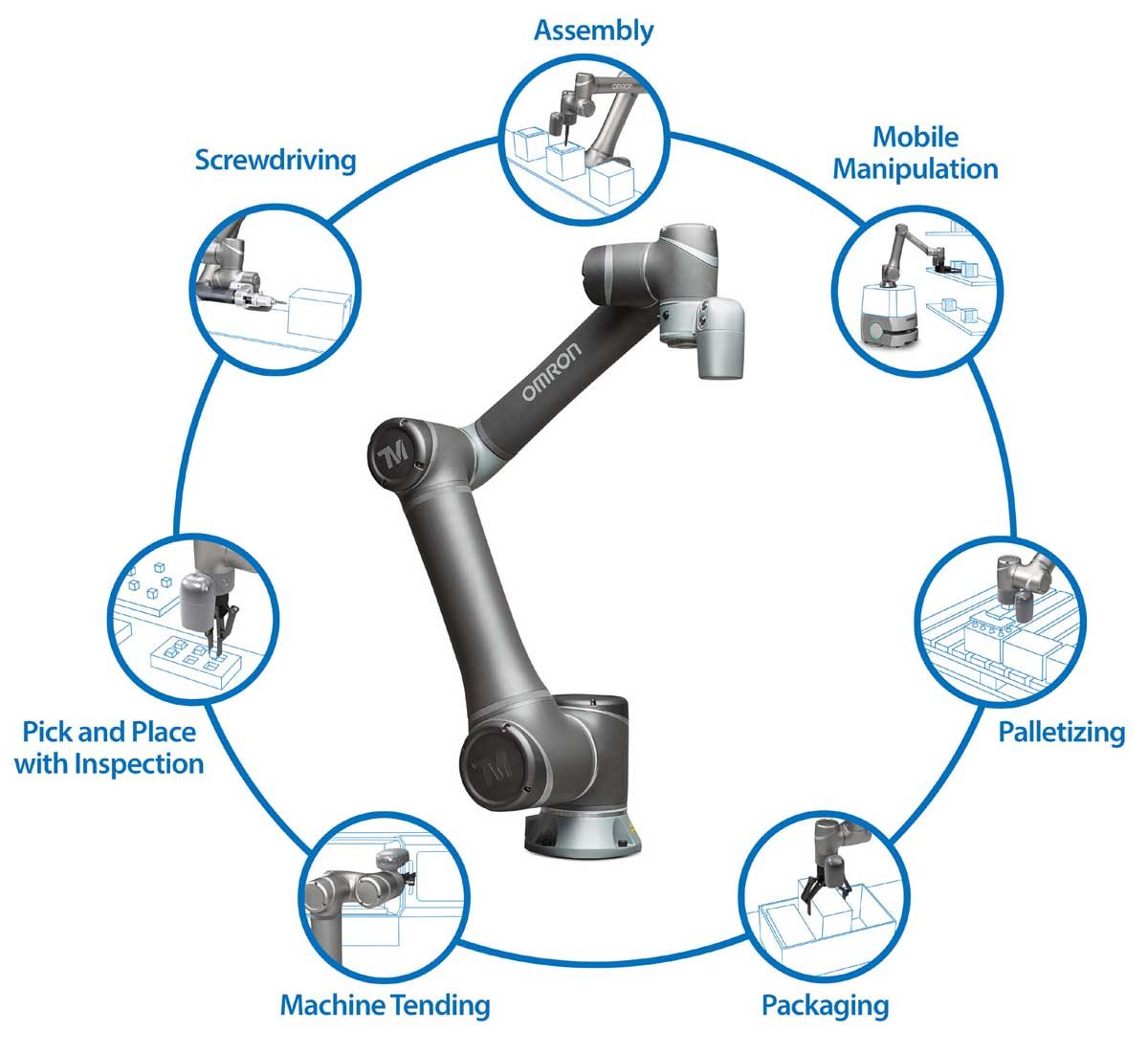

Omron Cobot TM Series

Industries & Applications

Industries

Semiconductor & Digital

Automotive

Food & Commodities

Applications

Assembly: Omron’s TM cobots improve throughput and consistency of repetitive or complex assembly tasks including part joining, insertion, tool changing, and working alongside people.

Palletizing: The TM Series are space-saving cobots can streamline end-of-line case stacking onto a pallet.

Packaging: Use TM cobots for inspecting and sorting products. Quickly adapt production lines to new products or seasonal models.

Machine Tending: Relieve workers from repetitive and dangerous tasks by using cobots to tend CNC machines, injection molding machines, stamping & punch pressers, grinding, and cutting machines.

Pick and Place with Inspection: The TM series features built-in vision system that allows for easy pick-and-place and inspection, without the need for installing additional cameras or lighting equipment.

Screwdriving: A complete ready-to-use solution is provided with a screw driving kit and pneumatic control box.

Cobot ROI Calculator

Download this free tool to help you calculate the payback period for collaborative robots and determine if cobots make sense for your business.