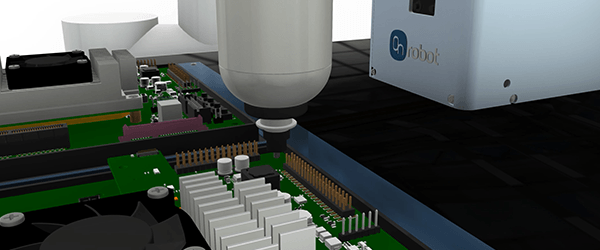

OnRobot Quick Changer for fast and easy tool changing.

The Quick Changer is the world’s easiest and fastest tool changer for end-of-arm tooling (EoAT) collaborative robot applications. It fits any end-of-arm tooling and enables the operator to change the end-of-arm tooling in just a few seconds.

The Quick Changer can handle 20kg payload and has a low built-in height and weight. It arrives with everything you need to get started right away.

The OnRobot Quick Changer is recommended for Universal Robots and other robots in the same class, as both input flange and output flange are fully compliant with the robot flange ISO standard.

- Easy and fast End-of-Arm-Tool changing in less than 5 seconds.

- With its low weight of only 200g (7 oz.), the Quick Changer has a low impact on the robot payload.

- Can be used on any robot arm, drone, or other equipment with an ISO-9409-1 flange

- Fully collaborative, simple to use, cost-effective, and has no sharp edges

- Integrates in all OnRobot tools and is easy to switch from one OnRobot tool to another on the major collaborative and light weight robot types

- No screwing required to attach a tool - redundant locking mechanism enables switching one tool to another without scewing

- Small size, high payload up to 20 kg (44 lb)

HOW TO BUILD A SCREWDRIVING APPLICATION

OnRobot Dual Quick Changer on two end-of-arm tooling attachments

The Dual Quick Changer offers the same flexibility and fast tool changing as the regular Quick Changer – but now, you can equip your robot with two end-of-arm tooling (EoAT) attachments simultaneously. By equipping your robotic arm with two end effectors, you enable the use of two tools in a single cycle, improving productivity by 50% or more. The Dual Quick Changer comes with a low built-in height and weight and is designed to fit all major robot brands. Consequently, you can use our tools interchangably with your existing robots for maximum efficiency.

The Dual Quick Changer enables you to use our end-of-arm tools together in a single cycle. With this innovative solution you can use two RG2 grippers or an RG6 gripper with a VG10 – it’s entirely up to you. Quickly and seamlessly switch between our tools to maximize the utilization of your robots with the Dual Quick Changer.

FEATURES:

- Easy and fast tool changing - Allows operators to quickly change tooling in addition to eliminating downtime between various processes.

- High repeatability - Ideal for CNC machine tending to speed up cycle time

- Safe and secure locking mechanism - Patented, reliable, and easy-to-use locking mechanism.

- Enables simple and fast locking and unlocking, letting even unexperienced operators change the robot’s EoAT in a few seconds.

- 20kg Payload - Can handle workpieces that combined weigh up to 20kg.

- ISO-9409-1 flange - Can be used on any robot arm, drone, or other equipment with an ISO-9409-1 flange.

How to Build a Pick & Place Application

Learn how to build a Pick & Place application with this detailed video guide. You will be presented with the best practices, considerations and main technical details needed to successfully deploy the application.

Learn how to grow your business with collaborative automation

With smarter and more adaptive tooling, collaborative robots now operate with greater speed, strength, safety and precision. And they can accomplish a wider range of tasks and fast ROI. Learn how you can increase production at lower costs.

Let us help find what you need.

Call 866.397.7388

Give us a call and get help right away. We're here for you!

Get in touch

Got a question or need more info? Contact us!

Request a Quote

Get pricing quickly. Fill out our Request For Quote form.