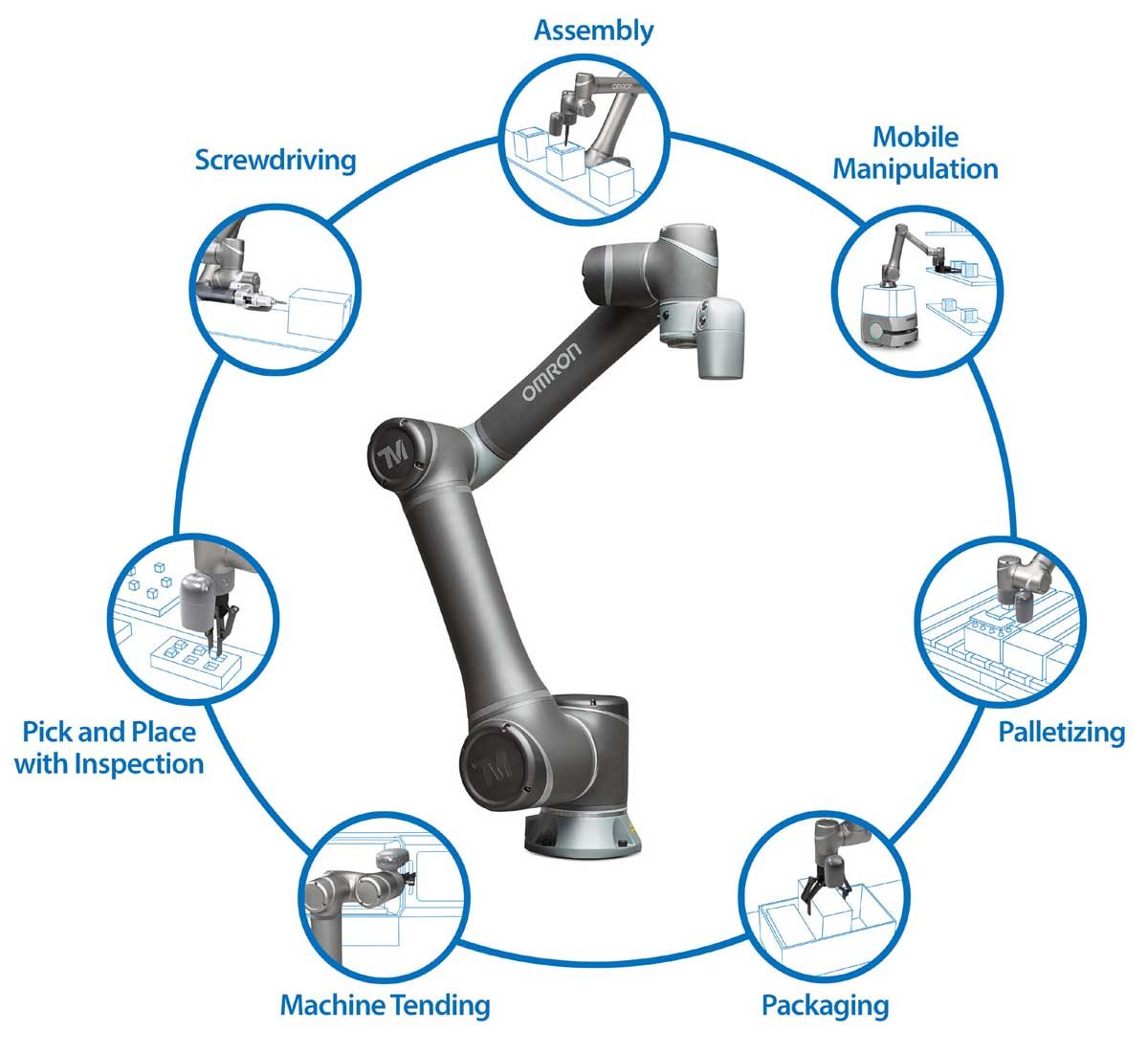

TM Series Cobots

Collaborative Robots for Manufacturing

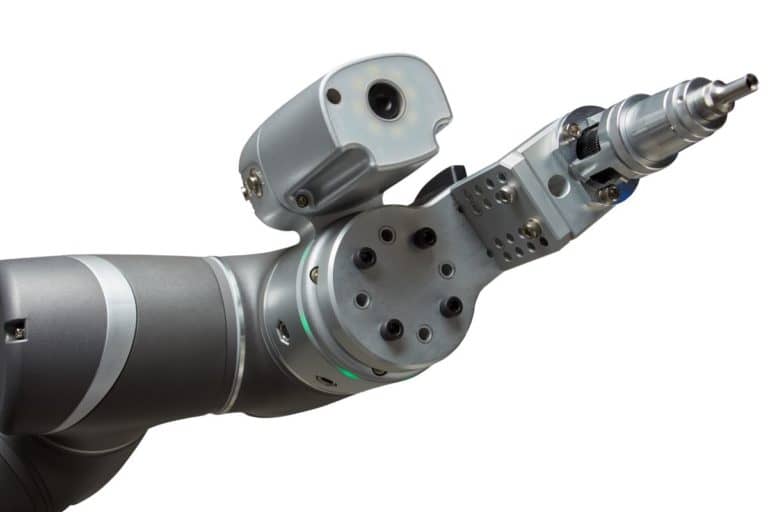

The TM Series is the only cobot on the market with a built-in vision system. Operators with no programming experience can be trained quickly and easily. It can handle many tasks like packaging, machine tending, assembly, welding, painting, buffing, or palletizing.