Encoders

MSI TEC is an authorized distributor of Encoder Products Company, a leading global manufacturer of motion sensing devices. They are recognized for producing the most complete line of incremental and absolute rotary encoders in the industry.

MSI TEC is an authorized distributor of Encoder Products Company, a leading global manufacturer of motion sensing devices. They are recognized for producing the most complete line of incremental and absolute rotary encoders in the industry.

An encoder is a sensing device, or an electromechanical feedback device, that converts motion to an electrical signal that can be read from a control device, such as a PLC or counter. Encoders indicate movement from one position to the next position and create signals using different technologies, like optical, mechanical, magnetic and resistive.

Encoders produce two types of signals: incremental or absolute. The difference between the two is that absolute encoders indicate a change of position and location change relative to shaft rotation. Incremental encoders only indicate that the position has changed, but not the specific position.

Specifying the right encoder for your application can be challenging due. We have the experience and expertise to help you choose the exact encoder for your needs, saving you time, money and frustration.

Absolute encoders provide position information for a rotating shaft. There are also two types of absolute encoders: single turn and multi-turn. Single turn absolute encoders provide information for any increment within one shaft rotation. Multi- turn absolute encoders retain absolute position data over the course of multiple shaft rotations. The encoder provides a unique digital code or bit for each increment of shaft rotation. Multi-turn absolute encoders store turns-counting information for instant retrieval, even after power down. MSI TEC provides single-turn and multi-turn absolute shaft encoders with a variety of housing sizes, shaft diameters, signal types and resolution.

Multi-turn blind hollow bore encoder

Size 36 mm (1.42")

SSI or CANopen®

DOWNLOAD DATASHEET

Multi-turn shaft encoder

Size 36 mm (1.42") package

SSI or CANopen® communications

DOWNLOAD DATASHEET

Single-turn shaft encoder

Low profile 1.55" single turn

Blind hollow or thru-bore

Parallel outputs

DOWNLOAD DATASHEET

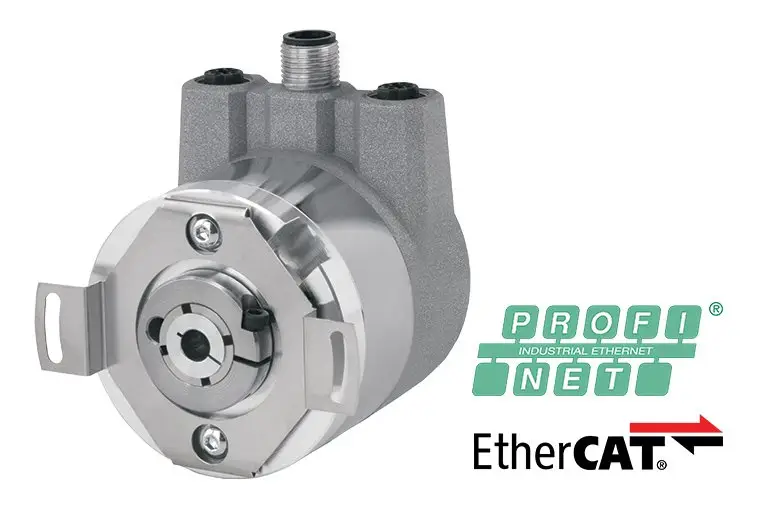

Single or multi-turn absolute shaft encoder

∅58 mm (2.28")

EtherCAT® or PROFINET®

DOWNLOAD DATASHEET

Single or multi-turn absolute shaft encoder

∅58 mm (2.28")

EtherCAT® or PROFINET®

DOWNLOAD DATASHEET

Single or multi-turn absolute blind hollow bore encoder

∅58 mm (2.28")

SSI or CANopen®

DOWNLOAD DATASHEET

Multi-turn absolute encoder

∅2.5"

SSI or CANopen® communications

DOWNLOAD DATASHEET

Robust Size 25 (2.5") single-turn absolute shaft encoder

Up to 12 bits with parallel outputs

IP67 sealing available

DOWNLOAD DATASHEET

Incremental signals provide a series of high and low waves that indicate movement from one position to the next. there is no special indication provided by the encoder to show the specific position, only an indication that the position has changed.

Incremental encoders are available in two basic output types: single channel and quadrature. a single channel encoder, often called a tachometer, is normally used in systems that rotate in only one direction and require simple position and velocity information. Quadrature encoders have dual channels (a and B) phased 90 electrical degrees apart. these two output signals determine the direction or rotation by detecting the leading or lagging signal in their phase relationship. Quadrature encoders provide high speed bi-directional information for complex motion control applications.

Size 20 stainless steel

IP67 sealing available

80 lb maximum axial and radial shaft loading

DOWNLOAD DATASHEET

Compact high-performance encoder

Low-profile ∅1.5"

Resolutions up to 10,000 CPR

DOWNLOAD DATASHEET

Programmable resolution, waveform & output type

Size 25 (2.5") shaft encoder

IP67 Sealing available

DOWNLOAD DATASHEET

The original industry-standard cube encoder

5 versatile housing styles

Bi-directional, constant pulse width

DOWNLOAD DATASHEET

High-performance, economical encoder

Low profile – 1.0" height and 1.5" diameter

Thru-bore or blind hollow bore with bores up to 0.375" (10 mm)

DOWNLOAD DATASHEET

Compact 1.5" incremental encoder

Resolutions up to 30,000 CPR

Flex mounting & large hollow bore option (up to 0.750")

DOWNLOAD DATASHEET

All metal housing

Easy installation on NEMA Size 23 or 34 motors

Up to 30,000 CPR

DOWNLOAD DATASHEET

Thru-bore modular encoder

Auto-aligning for high RPMs

Up to 12 pole commutation

0° to 100° C operating temperature available

DOWNLOAD DATASHEET

Give us a call and get help right away. We're here for you!

Got a question or need more info? Contact us!

Get pricing quickly. Fill out our Request For Quote form.

We use only necessary cookies on this website to provide the best user experience and customer service.