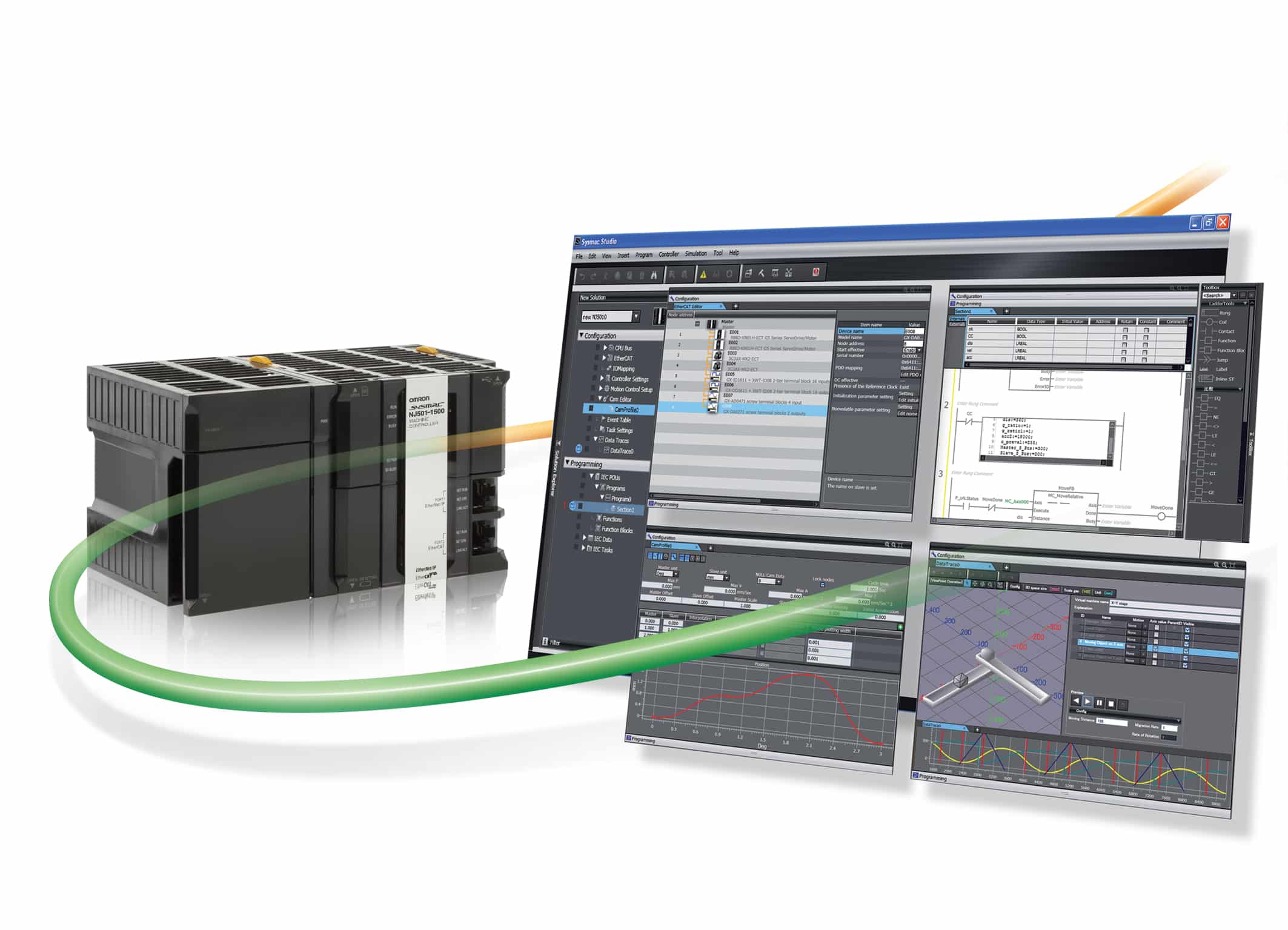

Sysmac studio

One Integrated Development Environment Software

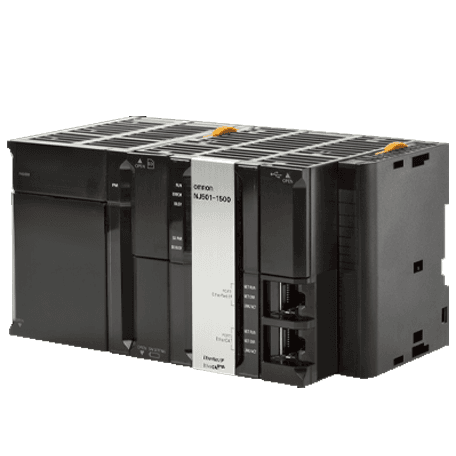

The Sysmac platform uses a single software program called the Sysmac Studio that gives you complete control over your automation system. It is integrates configuration, programming and monitoring. Graphics-oriented configuration allows quick set-up of the controller, field devices and networks while machine and motion programming based on IEC standard and PLCopen Function Blocks for Motion Control cuts programming time.

Smart Editor with On-line debugging helps quick and error free programming. Advanced simulation of sequence and motion control, and data trace reduce machine tuning and set-up.

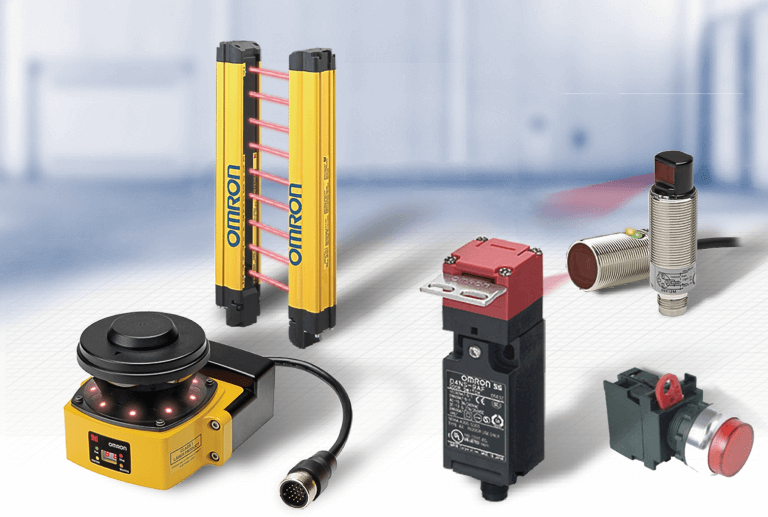

- One control for the entire machine or production cell

- Harmony between machine and people

- Open communication and open programming standards.