Remote I/O

Traditionally, every input and output was wired directly to a centralized PLC rack. On larger machines with hundreds or thousands of I/O points, this poses a logistical problem. One solution to this is Remote I/O, which allows for distributed blocks of I/O to be placed around a machine or factory, which then communicates back to the PLC via a network connection – commonly an industrial protocol like DeviceNet, EtherCAT, or Modbus/TCP. These come in many flavors (including for Safety devices), and can be very cost effective.

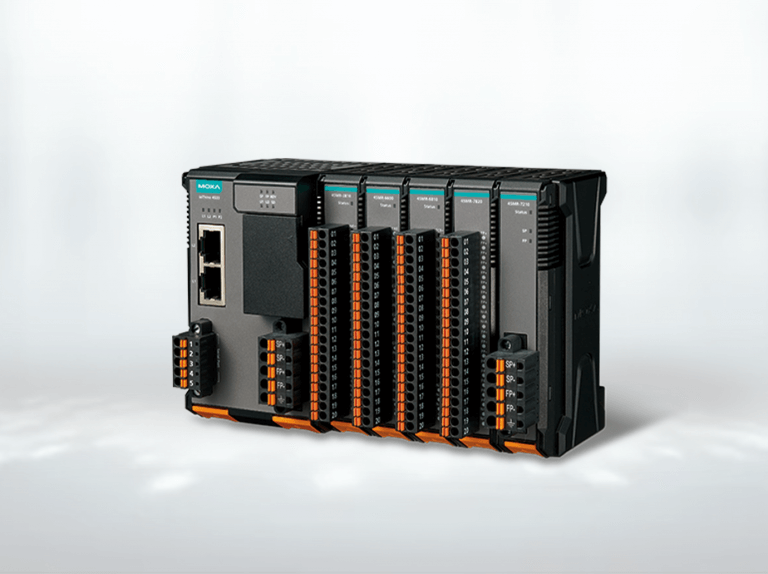

Moxa ioThinx: Advanced Remote I/O

Moxa’s advanced controllers and I/O products make it easier to realize complex IIoT applications such as energy management, factory machine management, transportation mangement, and remote asset management through expandable communication and high-performance data acquisition and control capabilities.

Weidmüller remote I/O systems

The rise in complexity of machines and systems is placing increasing demands on modern automation technology. Branched sub-systems need to be precisely integrated into complex topologies. A rapid and reliable transmission of signals and data is critical for smooth operation. Small and adaptable components which can be integrated in an application-specific manner are needed. Flexibility in the design and cabling of your systems, reliability in the transmission of signals and data, and very compact solutions – Weidmüller’s remote I/O systems for protection degrees IP 20 and IP 67 offer all this and more.

Moxa iOLogik Remote I/O

Moxa universal controllers and I/O products use Click&Go control logic, which includes a patented active monitoring technology and support for a versatile set of OT/IT protocols, to help you easily configure, deploy, and realize IIoT applications such as energy monitoring, facility monitoring, and machine OEM applications.

Resources

Moxa ioThinx 4500 Series - Advanced Modular Controllers & Remote I/O

Download Brochure!

Datasheets for Moxa 45MR Modules (for ioThinx 4500 Series)

Download Datasheets!

Datasheets for Moxa 4510 Series Modular Remote I/O Adapter

Download Datasheet!