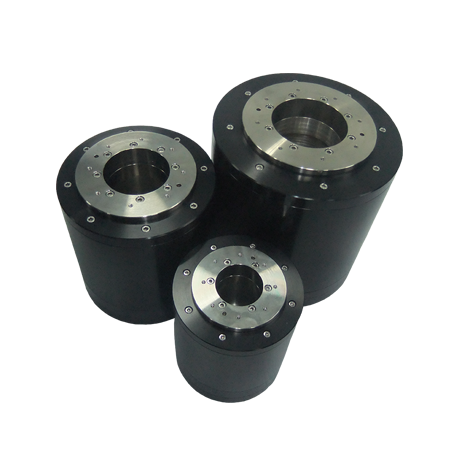

Industrial-strength machinery requires fast, precise motion and robust, high-performance rotary motion components. Akribis ADR-B Series rotary stages meet this demand by providing the best positioning performance to optimize machine productivity. ADR-B rotary stages leverage direct drive brush-less iron core motor technology to provide precise positioning for a wide range of industrial applications. Akribis’ direct drive iron core motor technology delivers the load handling, precision, repeatability, and high torque essential for heavy-duty equipment.

Not all rotary stages are equipped to perform in machine tools that operate at high speeds and carry heavy loads. To meet the needs of demanding equipment, motorized rotary stages should provide:

Akribis’ ADR-B Series of motorized rotary stages deliver all these benefits and more. They are designed for applications with large payloads and high torque and acceleration requirements. And they exhibit low cogging torque and precise homing through index pulse.

They also provide:

ADR-B motors are fully integrated with encoder and bearings and come with low-speed and high-speed windings.

Be the first to learn about classes, training, webinars, products news and more.

We use only necessary cookies on this website to provide the best user experience and customer service.