🎆Our offices are closed 2/16 for Presidents Day 🎆

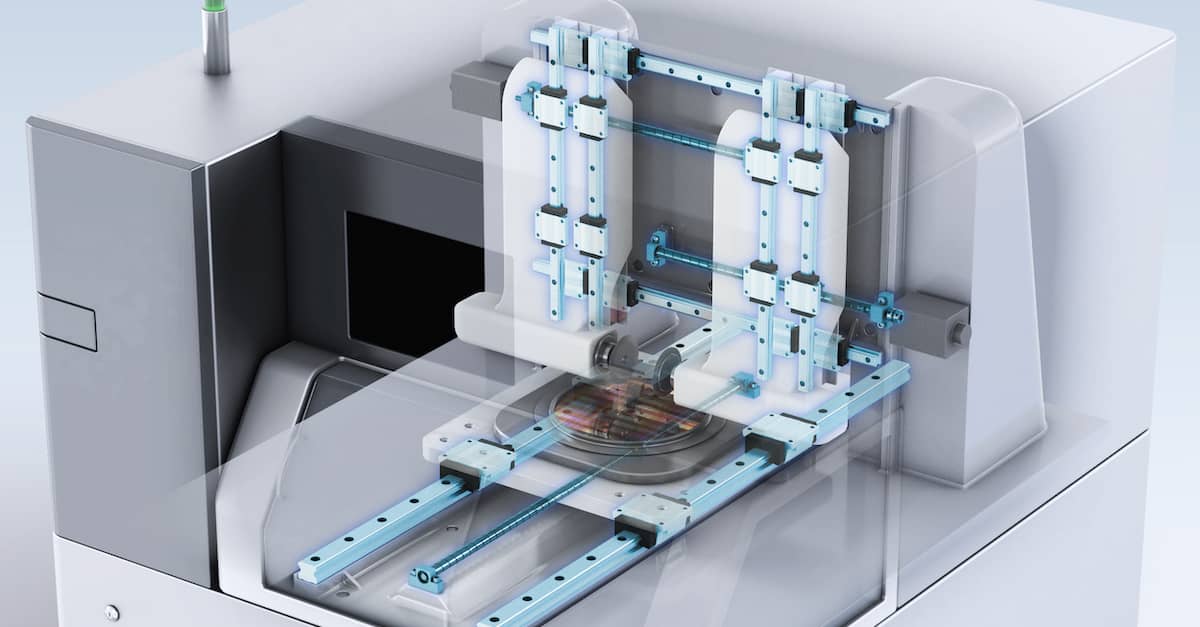

In the world of mechanical engineering and machine design, selecting the right components can make a profound difference in performance, reliability, and longevity. Among these crucial components, linear motion guides play a pivotal role, especially when precision and durability are paramount. This article delves into why THK’s linear motion guides stand out as the optimal choice for your machine build.

THK’s linear motion guides are renowned for their exceptional precision and accuracy. Utilizing advanced technologies and meticulous manufacturing processes, THK ensures minimal play and backlash, guaranteeing that your machine’s movements are precise and consistent. This level of precision is indispensable in industries where minute deviations can lead to significant repercussions.

Equipped with high-quality bearings and rails, THK linear motion guides deliver remarkably smooth and quiet operation. Whether your application requires rapid movements or slow, deliberate motions, THK guides ensure minimal friction and noise, enhancing operational efficiency and user comfort.

THK’s commitment to engineering excellence is evident in their linear motion guides’ robust design, capable of supporting high radial and axial loads. This capability is crucial for machines handling heavy workpieces or operating under dynamic conditions, providing reliability and stability even in demanding environments.

Crafted from premium materials such as hardened steel and corrosion-resistant alloys, THK linear motion guides are built to endure rigorous use over extended periods. Their superior durability minimizes maintenance requirements and downtime, ensuring uninterrupted operation and longevity of your machinery investment.

THK offers a comprehensive range of linear motion guides tailored to diverse applications and specifications. From different profile types (round, square, and more) to varied sizes and load capacities, THK guides can be customized to meet specific performance criteria. This versatility allows engineers to optimize machine designs for maximum efficiency and functionality.

In today’s era of automation, seamless integration with control systems is paramount for enhancing productivity and operational efficiency. THK’s linear motion guides are designed to integrate seamlessly with automated machinery, facilitating precise control and synchronization. This compatibility ensures that your machines operate at peak performance, meeting the demands of modern manufacturing environments.

Despite their advanced features and capabilities, THK linear motion guides offer excellent value and cost-effectiveness. Their initial investment pays off through improved performance, reduced maintenance costs, and extended service life compared to alternative motion systems. This makes THK guides a wise investment for companies aiming to optimize production processes and achieve superior return on investment.

MSI TEC is an authorized THK distributor. Whether you are designing a new machine or upgrading existing equipment, we can help you to achieve unparalleled performance and reliability in your manufacturing operations. Contact us to discuss your project.

Be the first to learn about classes, training, webinars, products news and more.

We use only necessary cookies on this website to provide the best user experience and customer service.