🎆Our offices are closed 2/16 for Presidents Day 🎆

When you’re in the machine manufacturing business, design errors can have far-reaching consequences. Building a machine involves multiple steps, including design, procuring components, construction, and testing. Many design errors only become apparent after the machine has been assembled and is in operation. The further along in the process you are before discovering a mistake, the greater the scope of the damage and the range of people it will affect.

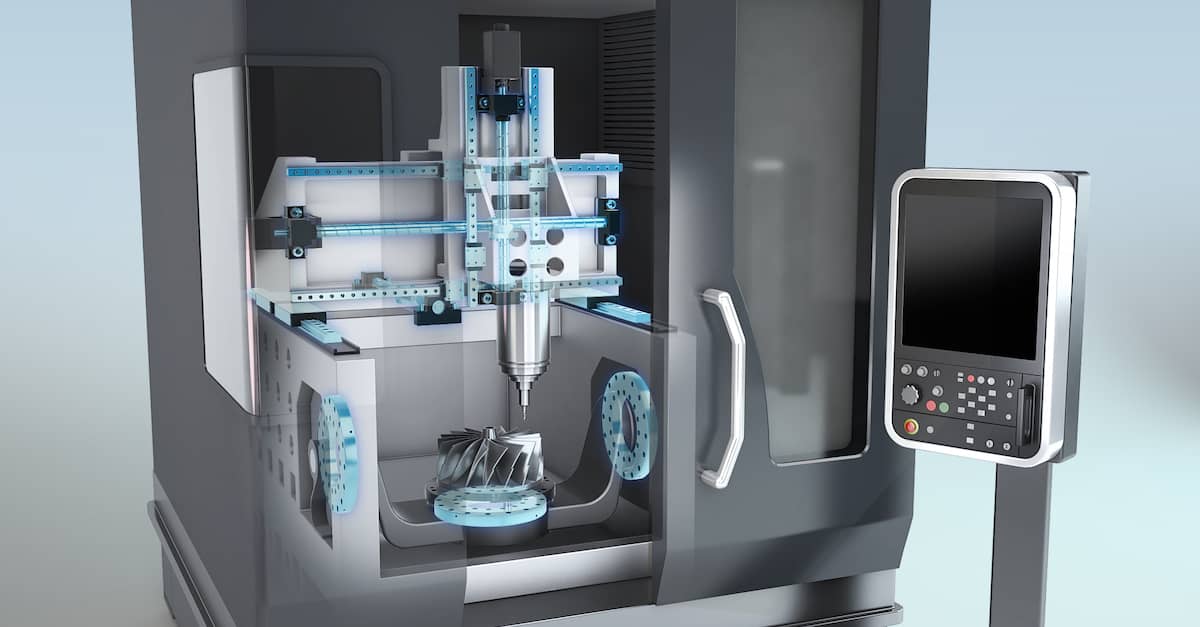

Linear motion systems are crucial components in many machines, playing a significant role in their functionality and efficiency. There are various types of linear motion systems to choose from, each with its strengths and weaknesses. If you’re not a linear motion system expert, it’s easy to lose your way in a sea of choices. Even after deciding on a type of system, complex calculations are needed to ensure that the system will meet your needs. Mistakes in these calculations could mean that the linear motion system could be damaged during testing or normal use, negatively impacting your company’s bottom line and your relationship with customers.

Consider a machine that has taken six months to go from initial design to testing. During the design phase, the cost of correcting a mistake is minimal: some time spent by the designer and possibly some components purchased for testing. Even a major miscalculation at this stage can be corrected without wide-ranging impacts. However, if a mistake goes undiscovered until the testing phase, the results can be catastrophic. If the machine doesn’t operate with the expected accuracy or produces excessive noise, heat, or vibration, you could face the loss of up to six months of effort from not just the design department, but also the purchasing and operations departments. When this happens, it destroys any hope of completing the machine on time or within budget.

Linear motion systems are complex and vital components in many machines, but their design can be challenging, and the price of mistakes is high. An incorrectly designed linear motion system can easily lead to a machine that is inaccurate, behaves abnormally, or has a reduced service life.

So how can you avoid design mistakes or detect them while they are still cost-effective to fix? As an authorized THK distributor, MSI TEC has deep experience with linear motion systems and can help prevent problems and protect your company from potential losses.

When mistakes are made in the linear motion system design, the entire function of the machine is in jeopardy. If a linear motion system fails, it usually means the whole machine has failed. Here are some reasons why linear motion systems are so important in machinery design:

This last point is especially important when designing machines for which maintenance and downtime are expensive. Machinery that is vital to a core process or installed in hard-to-access locations requires components with long service lives to avoid driving up overall maintenance costs.

When designing a linear motion system, consider the following factors to avoid mistakes:

Early detection of design mistakes can save significant time and money. Conduct thorough testing at each design stage and involve experts who can identify potential issues before they become costly problems. Partnering with experienced distributors like MSI TEC can provide valuable insights and support throughout the design and implementation process.

Be the first to learn about classes, training, webinars, products news and more.

We use only necessary cookies on this website to provide the best user experience and customer service.