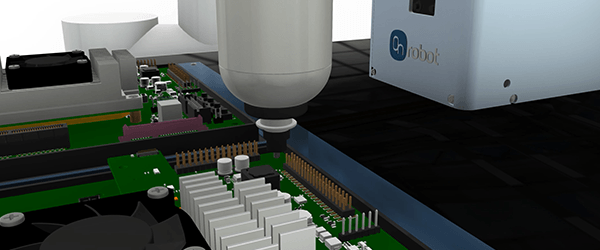

OnRobot Robot Screwdriver and Screw Feeder

Easily automate assembly processes with OnRobot’s intelligent Screwdriver designed for light industrial and collaborative robots. Automating screw driving tasks have never been easier or more cost-effective. The OnRobot screwdriver arrives with everything you need right out of the box. Simply mount the screwdriver on any leading robot arm and install the appropriate bit, then enter screw length and torque directly into the robot’s user interface. Precise torque control and embedded axis eliminate the time and cost for additional integration and ensures consistent, accurate screw insertion. Changeovers to a different screw type or size take just minutes, reducing downtime and boosting ROI.

The OnRobot Screwdriver and available screw feeders handle a wide range of screw sizes from M1.6 to M6 and up to 50mm long. Precise torque control ranges from 0.15 Nm to 5 Nm. More versatile and intelligent than traditional tools, the OnRobot Screwdriver can detect if the screw is picked, is the correct length or been properly inserted during the tightening process.

FEATURES:

- Complete screwdriving solution includes screw feeder and the easy One System setup for any leading robot brand.

- Screws up to 30mm long are withdrawn inside the screwdriver when moving. Safety stop automatically activates if a screw is exposed to excessive force

- Screws are retracted inside the tool and driven automatically once the robot arm moves into position, which reduces robot arm movement and simplified programming

- Handles screw sizes from M1.6 to M6 up to 50mm long. Change-overs to a different screw type or size take just minutes, reducing downtime and boosting ROI.

- Torque control ranges from 0.15 Nm to 5 Nm for consistent and accurate screwdriving

- ESD Certified and suited for all assembly environments, including electronics

HOW TO BUILD A SCREWDRIVING APPLICATION

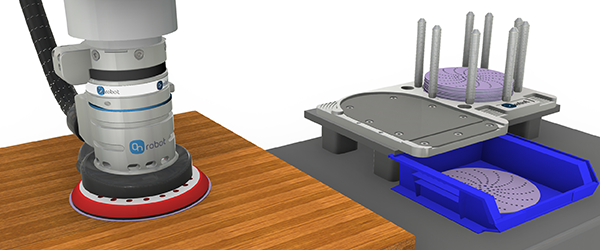

OnRobot Sander

Sanding and polishing tasks are a dirty and dangerous job for workers. OnRobot offers a solution with its electric, random orbital sander that can be used with all major collaborative and lightweight industrial robots. It makes automating surface finishing applications, like sanding, buffing and polishing, fast and painless.

The OnRobot Sander operates without external air supply, eliminating the dust and noise generated by traditional air sanders. Use this flexible tool for a wide range of part geometries and materials to get greater consistency, higher finish quality, and lower scrap rate. You’ll reduce workplace dust due to the use of standard 3M clean sandpaper discs and reduce the risk of worker injury from the vibration of manual sanders.

The OnRobot sander arrives ready to go and includes:

- Plug-and-play sanding tool

- A variety of standard sanding and polishing discs

- Easy-to-use software

- Automated Grit Changer

- Force torque sensor

FEATURES:

- Reduce workplace dust due to the use of standard 3M clean sandpaper discs and reduce the risk of worker injury from the vibration of manual sanders.

- Fast and easy setup with the ability to quickly program and re-program material removal and finishing tasks.

- Flexible for wide range of materials and geometries.

- Replaceable standard sanding discs and easy adjustment of tool rotation speed ensures high quality surface finishing.

- Powerful electric sander does not require compressed air which reduces maintenance costs.

- Includes an optional grit changer that lets you switch between different sanding discs - without the need for operator intervention.

- Compliant with local health and safety regulations.

- Get better consistency, higher finish quality, and lower scrap rate.

- All of the advanced features of the OnRobot Sander are supported on Universal Robots arms, but the tool is easily integrated with any major robot brand.

HOW TO BUILD A SANDING APPLICATION

Learn how to build a Sanding application with this detailed video guide. You will be presented with the best practices, considerations and main technical details needed to successfully deploy the application.

Learn how to grow your business with collaborative automation

With smarter and more adaptive tooling, collaborative robots now operate with greater speed, strength, safety and precision. And they can accomplish a wider range of tasks and fast ROI. Learn how you can increase production at lower costs.

Let us help find what you need.

Call 866.397.7388

Give us a call and get help right away. We're here for you!

Get in touch

Got a question or need more info? Contact us!

Request a Quote

Get pricing quickly. Fill out our Request For Quote form.