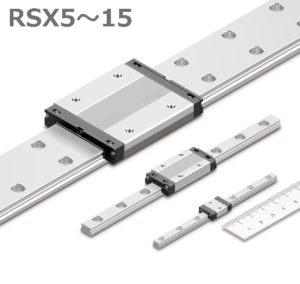

Product Spotlight: THK Aerospace Products

The aerospace industry requires high performance systems and components that can withstand extreme conditions. Motion control products from THK are designed specifically for use in vacuums and challenging aerospace environments. Their LM Guides, Ball Splines