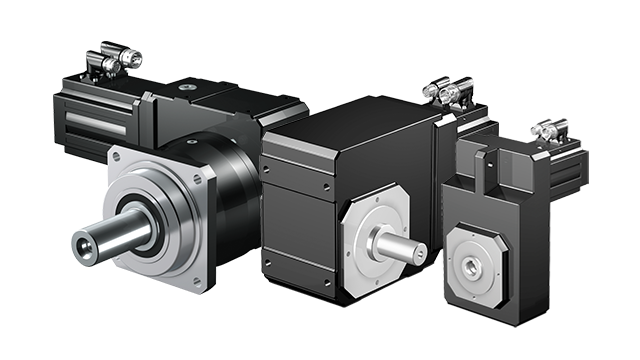

Right Angle Geared Motors

STOBER servo right-angle geared motors are available as planetary right-angle geared motors and helical-bevel geared motors. These super compact synchronous servo motors are ideal for highly dynamic applications. All drive units are provided with high-quality helical gearing for unrivalled smoothness of running and backlash stability. Backlash down to ≤1.5 arcmin.

- Outputs: Hollow bore, Shaft output (K), Shaft with or without key (KL), Single or double wobble free bushing

- Housing Styles: Output flange (Round for K, Square for KL), Pitch circle diameter tapped holes, Foot mounting, Torque arm bracket (K only)

- IP Ratings: 65 standard, 56, 66

- Package Options (A package includes coating, lubrication, and output material):

- Standard Duty – RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty – 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty – 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

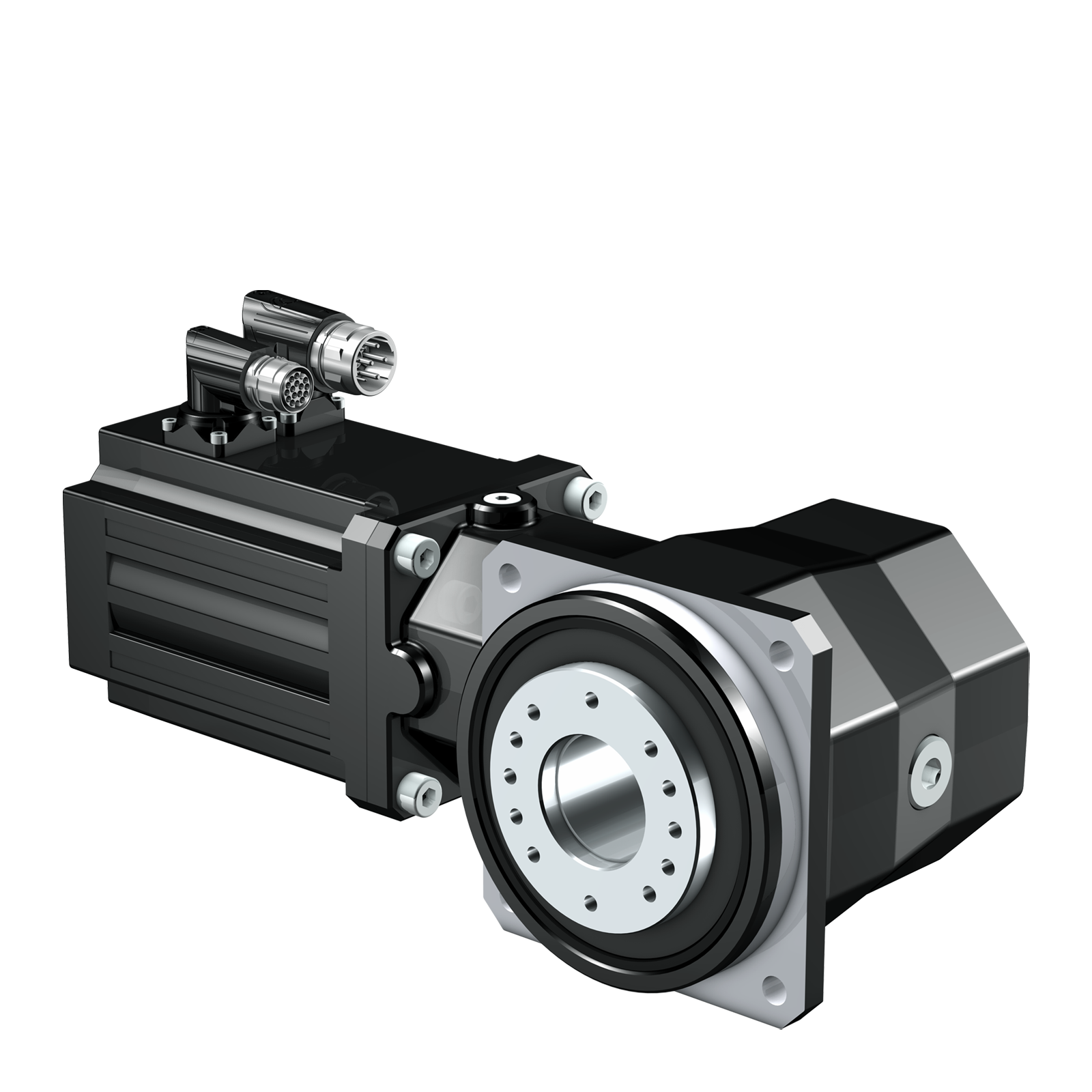

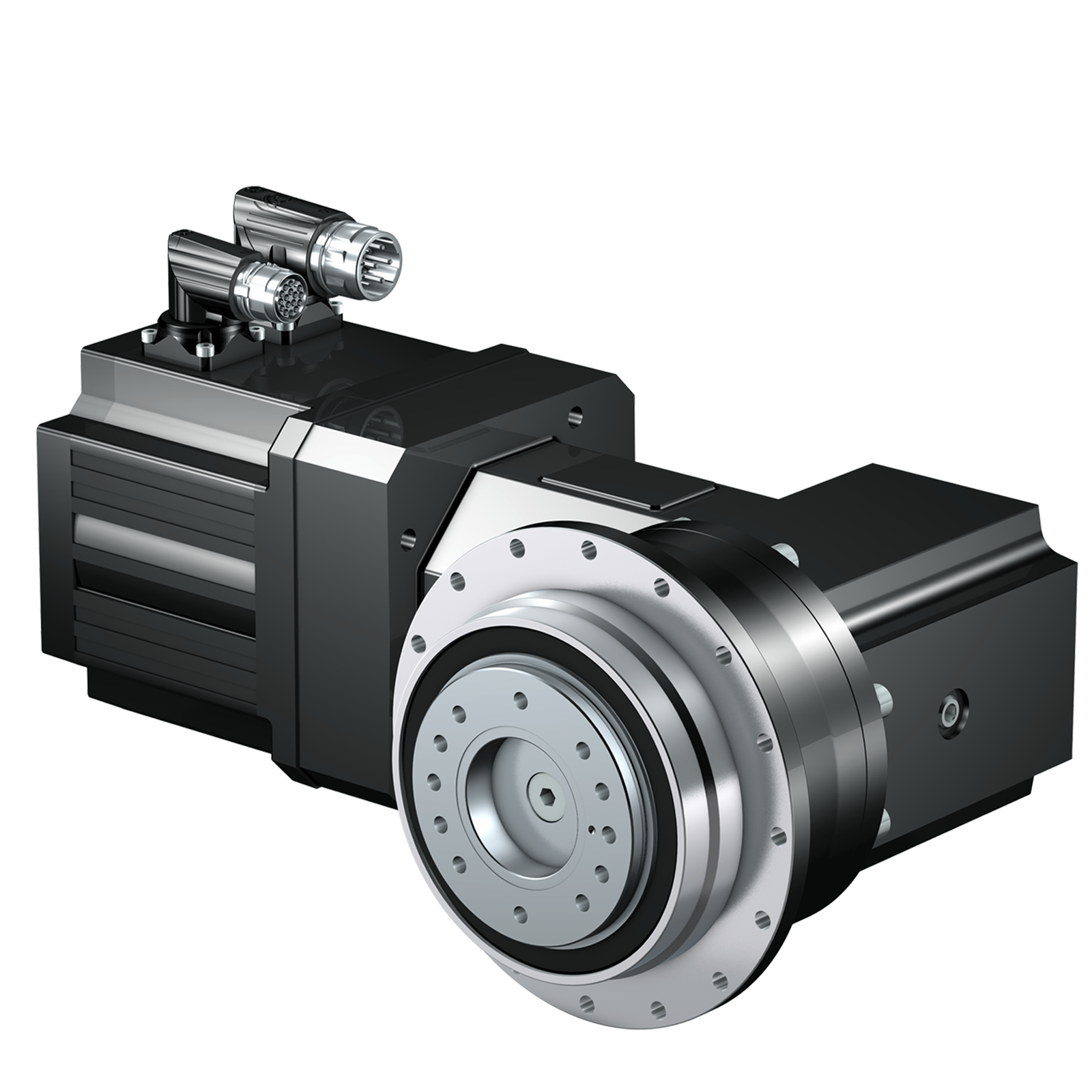

K/KL Series

For the most versatility in mounting and outputs

The K/KL series is unparalleled when it comes to right angle options. This synchronous servo geared motor’s unique design allows you to use a variety of outputs, including shaft, hollow bore, shrink rings, and bushings. Housing options include flange, feet, and torque arm. They feature helical bevel gearing, providing smooth motion and optimal efficiency.

- Outputs: Hollow bore, Shaft output (K), Shaft with or without key (KL), Single or double wobble free bushing

- Housing Styles: Output flange (Round for K, Square for KL), Pitch circle diameter tapped holes, Foot mounting, Torque arm bracket (K only)

- Total gear ratio range: 4 – 381

- Acceleration torque: 22 – 13,200 Nm

- Nominal torque: 15 – 12,000 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 725 Nm/arcmin

- Find your right fit with Stober’s Configurator

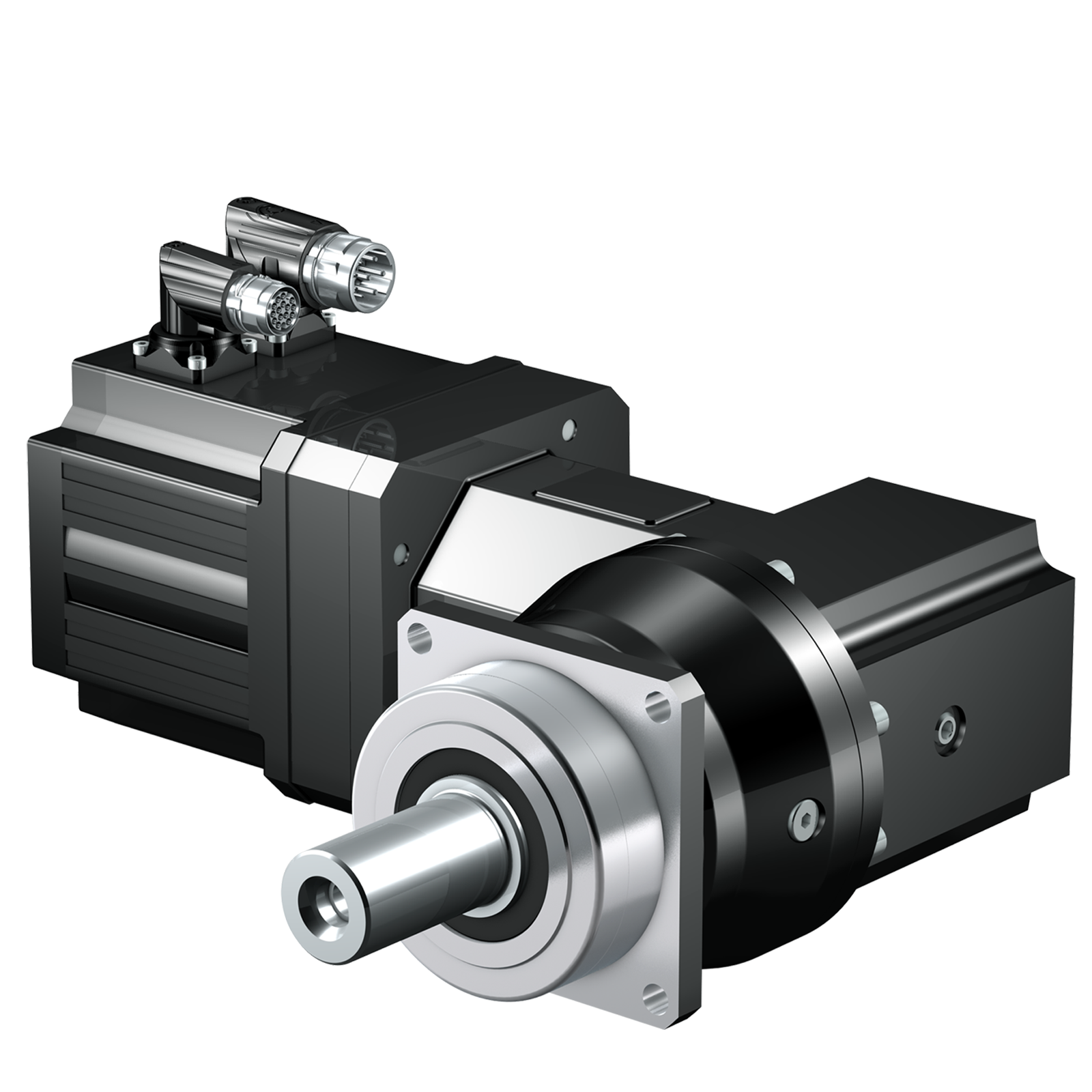

PKX_EZ Series

For smaller machine envelopes

The PKX series combines our planetary P series with a KX series input. This synchronous servo geared motor features a compact design and has superior stiffness and precision compared to a K series unit.

- Total gear ratio range: 3 – 300

- Acceleration torque: 11 – 3,300 Nm

- Nominal torque: 15 – 2,387 Nm

- Continuous Input Speed: Up to 3,500 RPM

- Cyclic Input Speed: Up to 6,000 RPM

- Torsional Stiffness: Up to 393 Nm/arcmin

- Find your right fit with Stober’s Configurator

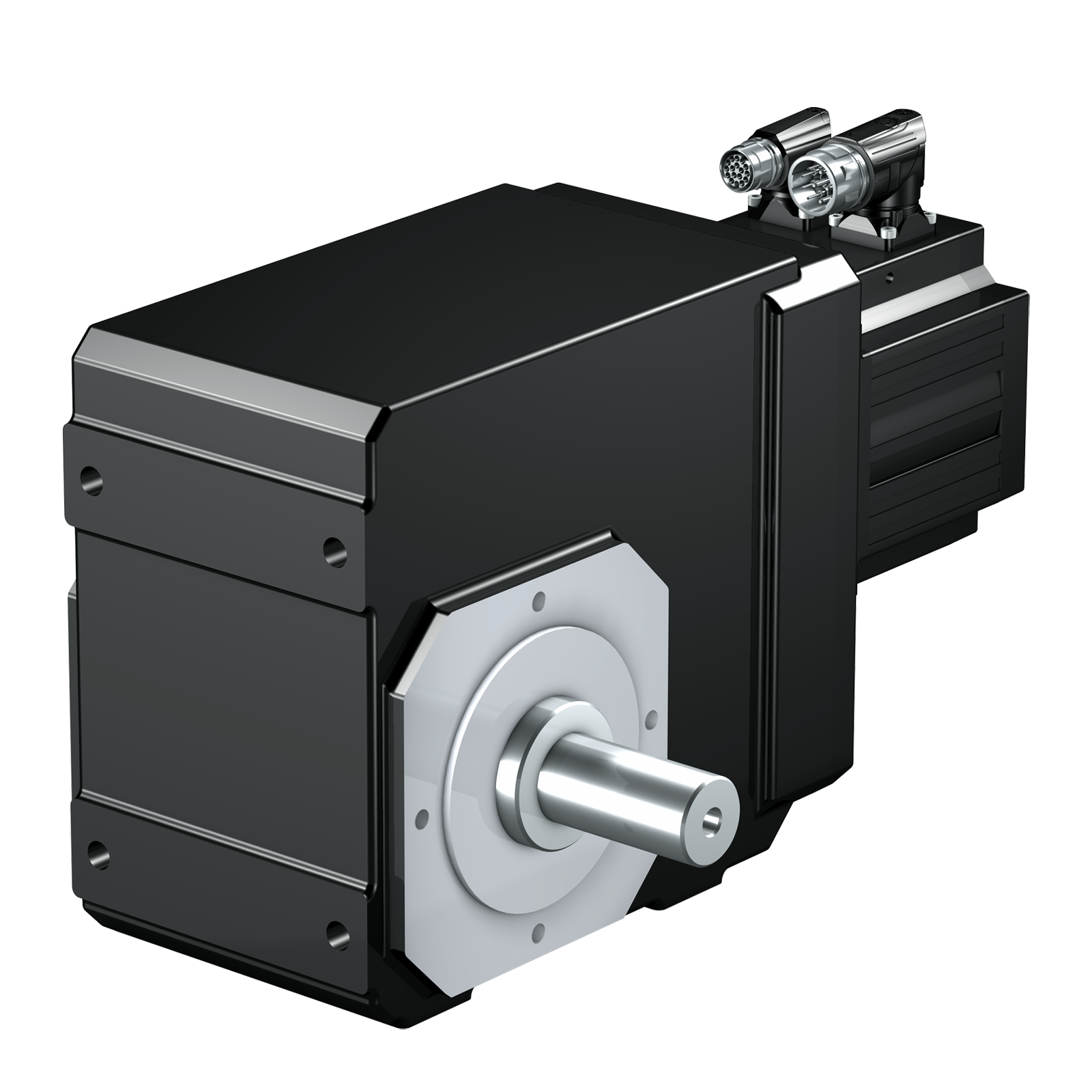

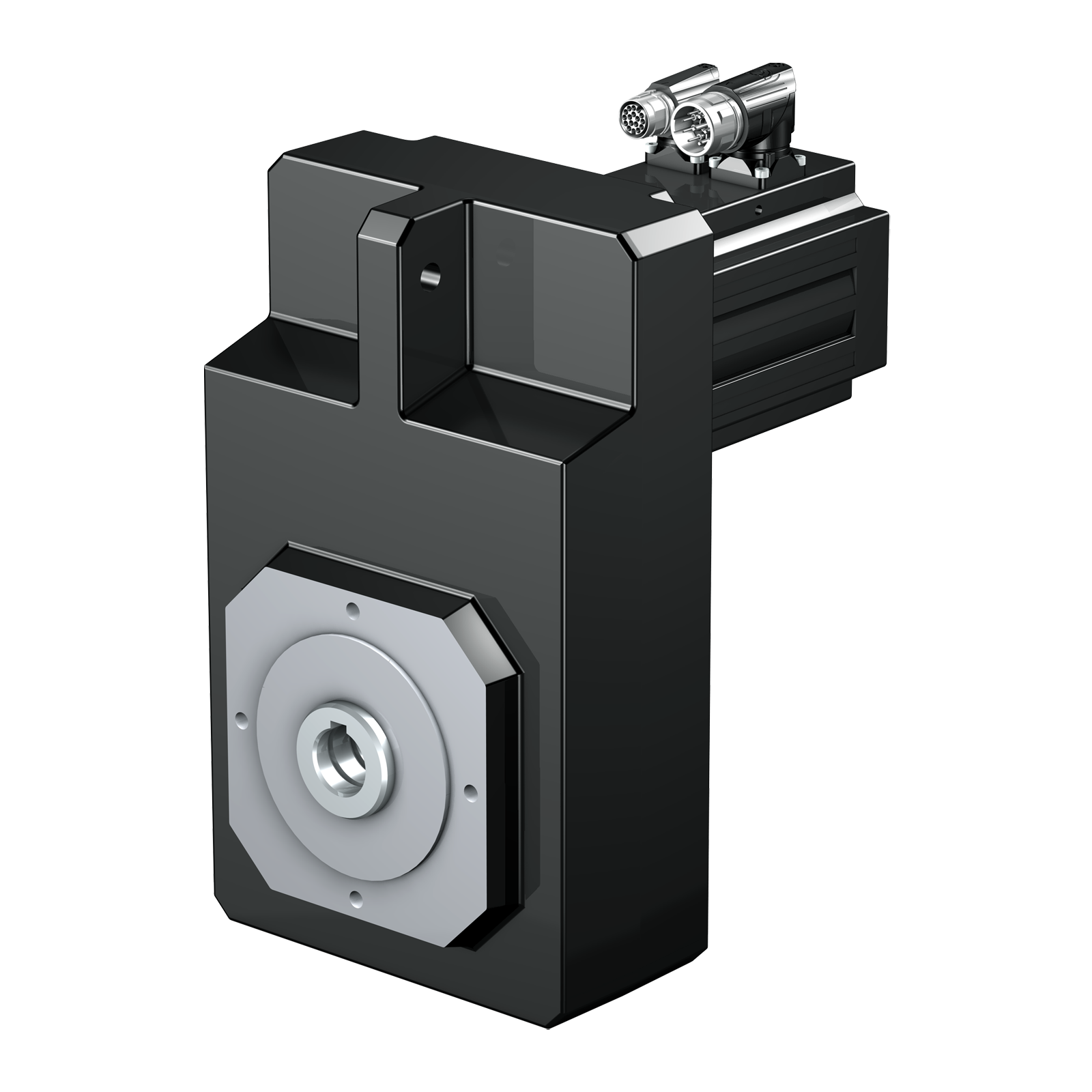

KS_EZ Series

For mounting flexibility with low backlash

- Total gear ratio range: 6 – 200

- Acceleration torque: 90 – 400 Nm

- Nominal torque: 60 – 250 Nm

- Continuous Input Speed: Up to 4,500 RPM

- Cyclic Input Speed: Up to 6,000 RPM

- Torsional Stiffness: Up to 42 Nm/arcmin

- Find your right fit with Stober’s Configurator

F _EZSeries

For mounting flexibility

- Total gear ratio range: 4.3 – 552

- Acceleration torque: 78 – 1,100 Nm

- Nominal torque: 69 – 1,100 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 77.4 Nm/arcmin

- Find your right fit with Stober’s Configurator

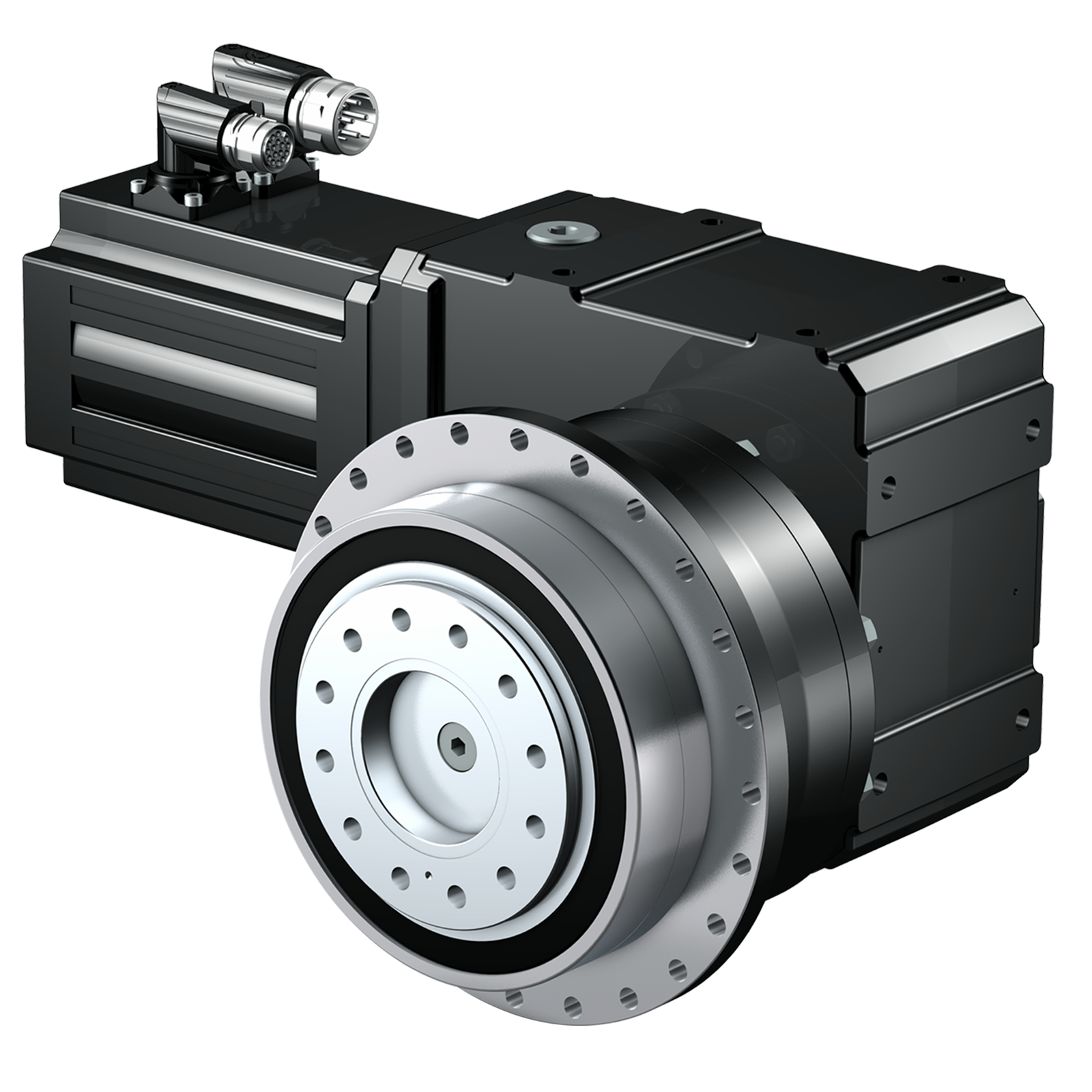

PHK_EZ Series

For high input speeds and low noise

- Total gear ratio range: 16 – 561

- Acceleration torque: 277 – 7,207 Nm

- Nominal torque: 210 – 5,000 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 1,210 Nm/arcmin

- Find your right fit with Stober’s Configurator

PHKX_EZ Series

PHKX_EZ: For smaller machine envelopes

The PHKX series combines our planetary PH series with a KX series input. This synchronous servo geared motor features a compact design and has superior stiffness and precision compared to a K series unit.

- Total gear ratio range: 4 – 300

- Acceleration torque: 60 – 2,100 Nm

- Nominal torque: 36 – 1,557 Nm

- Continuous Input Speed: Up to 3,500 RPM

- Cyclic Input Speed: Up to 6,000 RPM

- Torsional Stiffness: Up to 489 Nm/arcmin

- Find your right fit with Stober’s Configurator

PHQK_EZ Series

For the ultimate torque density and power

- Total gear ratio range: 22 – 2,242

- Acceleration torque: 316 – 43,000 Nm

- Nominal torque: 264 – 21,772 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 4,664 Nm/arcmin

- Find your right fit with Stober’s Configurator

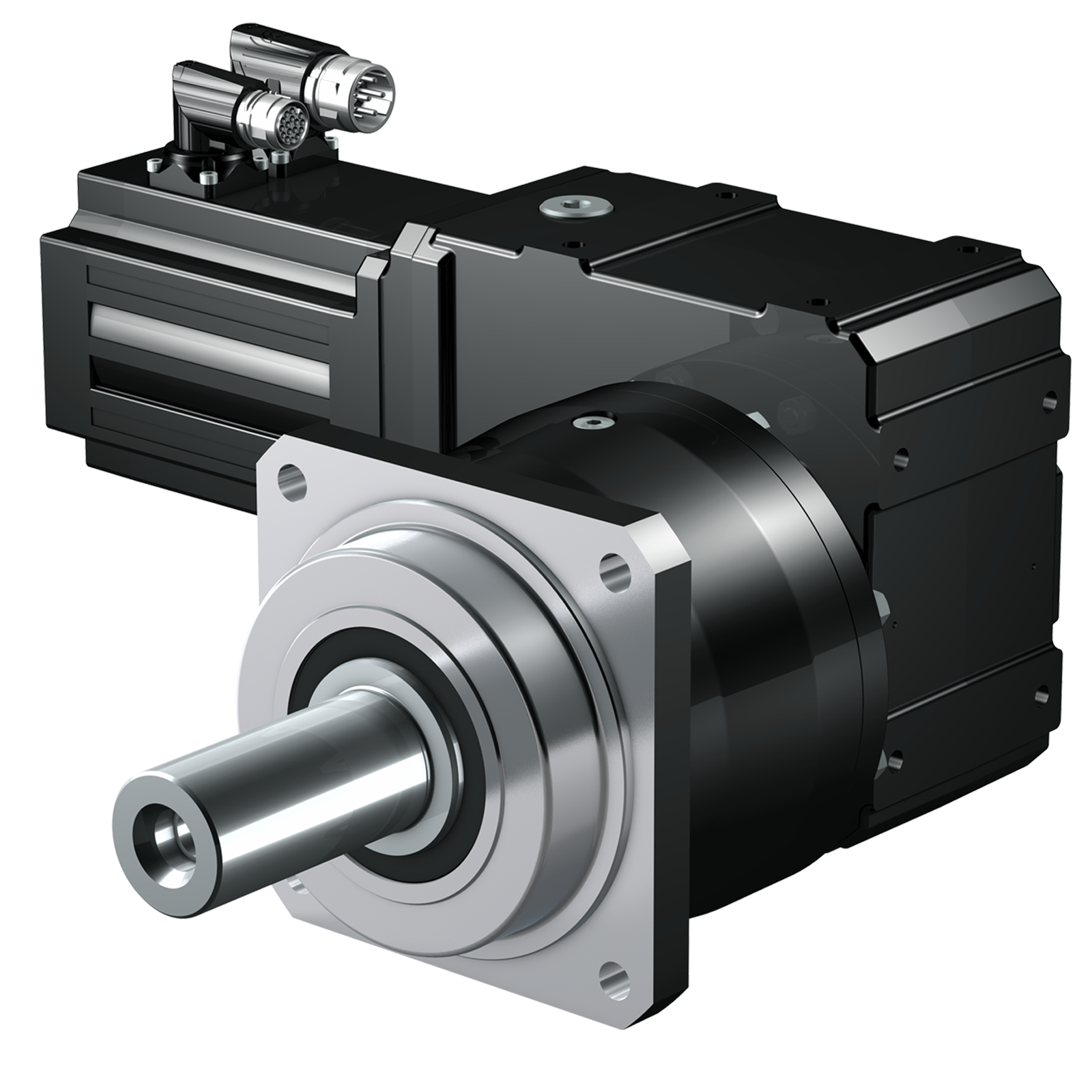

PK_EZ Series

For high input speeds and low noise

- Total gear ratio range: 12 – 561

- Acceleration torque: 200 – 3,105 Nm

- Nominal torque: 120 – 2,100 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 305 Nm/arcmin

- Find your right fit with Stober’s Configurator

Discover the Stober Advantage

- Superior Components

- Precision gearing for longer life

- Optimized Design

- State-of-the-art inspection and testing

Let us help find what you need.

Call 866.397.7388

Give us a call and get help right away. We're here for you!

Get in touch

Got a question or need more info? Contact us!

Request a Quote

Get pricing quickly. Fill out our Request For Quote form.